Table of Contents

That piece of wood under your feet, the one that lets you ollie, grind, and maybe occasionally eat pavement? It's more than just a plank. how skateboard decks are made is a fascinating blend of material science and skilled craftsmanship. From carefully selected trees to the final pressing, each step plays a vital role in creating the sturdy yet flexible platform that defines the skateboarding experience. This article will guide you through the process of how skateboard decks are made, revealing the processes and materials that transform raw wood into the foundation of your ride.

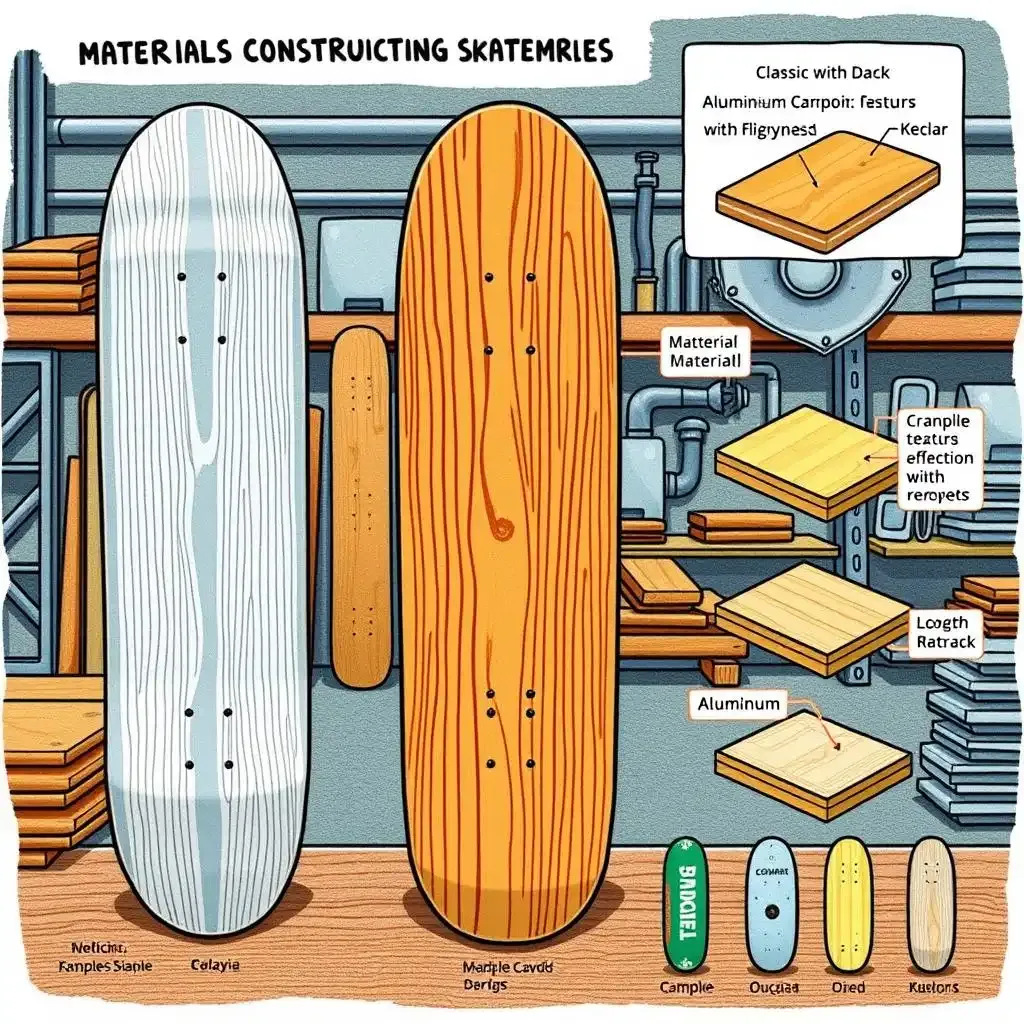

Key Aspect | Details |

|---|---|

Material | Typically seven layers of North American maple. Colder climates produce denser, preferred wood. |

Veneer Creation | Logs are soaked in hot water, then spun against a knife to create thin sheets (veneers). |

Adhesive | Polyvinyl glues are used to bond the maple veneers together. |

Pressing | Veneers are pressed in a mold to achieve the desired deck shape. |

Alternative Materials | While maple is standard, some decks use composites, aluminum, or fiberglass. |

Shape and Size | Varies based on skateboarding style and intended terrain. |

Material Matters: How Skateboard Decks Begin

Material Matters How Skateboard Decks Begin

From Forest to Factory: The Mighty Maple

Ever wondered what makes your skateboard so strong but still able to bend when you need it to? It all starts with the wood, and most of the time, that wood is maple. Not just any maple, but the kind that grows in North America. Think of these maple trees like the superheroes of the forest. They have this amazing combination of strength and bendiness, kind of like how your favorite action figure can take a beating but still strike a cool pose. This special maple is super important because it needs to handle all the jumps, flips, and sidewalk cracks we throw at it.

Softening Up: Making Veneers

Okay, so we've got these tough maple logs. But you can't just slap a log on some wheels and call it a skateboard, right? The first step is turning those logs into thin layers of wood called veneers. Imagine a giant pencil sharpener, but instead of making pointy tips, it shaves off super thin sheets of wood. To make this easier, they soak the logs in hot water first. This is like giving the wood a warm bath so it gets nice and soft, making it easier to slice into those veneers. This process is crucial for creating the multiple layers that make up your deck. Did you know that skateboarding can be risky if your board isn't up to the task?

The Pressing Question: How Skateboard Decks Are Formed

Alright, so imagine this: we've got stacks of these bendy veneers, almost like a deck of cards made of wood. The big question is, how do we turn this floppy stack into the solid thing we ollie and grind on? Well, this is where the "pressing" part of how skateboard decks are made comes in. Think of it like making a super strong, multi-layered sandwich, but instead of peanut butter and jelly, we're using glue – special polyvinyl glue, to be exact. They slather this glue on each veneer, making sure every layer sticks together like best buds. Then, these glued-up veneers are placed in a mold. This isn't just any mold; it's shaped exactly like a skateboard deck, with that cool concave curve we all know and love. Imagine a giant waffle iron, but instead of waffles, it's pressing out skateboard decks! This intense pressure and the glue work together to fuse those seven layers into one solid piece. It's kind of like how pressure turns coal into a diamond, but instead of a shiny gem, we get the heart of our skateboard. Speaking of sturdy, you might be wondering about skateboard trucks and how they fit into the think about later on.

Beyond the Basics: Variations in How Skateboard Decks Are Made

Beyond The Basics Variations In How Skateboard Decks Are Made

Thinking Outside the Maple Box

Okay, so maple is like the star player on the skateboard team, but sometimes folks like to mix things up. Think of it like ordering pizza – pepperoni is classic, but sometimes you want to try mushrooms or pineapple, right? Well, the same goes for skateboard decks. While most are made of maple, some adventurous souls and companies experiment with other materials. Imagine a skateboard made of metal! That's what happens with aluminum decks. They're super strong, like a superhero's shield, but they can feel a bit different under your feet. Then there are composite decks, which are like a recipe mixing different ingredients like fiberglass or even Kevlar – the stuff they use in bulletproof vests! These decks can be lighter or have a unique feel. It’s all about finding the right flavor, or rather, the right feel for your ride. Ever wonder if skateboards are vehicles? These alternative materials might make you think twice!

Deck Shapes and Sizes: It's Not One-Size-Fits-All

Now, let's talk shapes. You might think all skateboards look the same, but if you really look, you'll see they've got different curves and sizes. It’s like shoes – you wouldn't try to play basketball in flip-flops, would you? Different skateboard shapes are better for different things. Some decks are wider, which can be great for cruising around, feeling stable like a tank. Others are narrower, making them easier to flip and do tricks, like a ninja on wheels. The curves on the sides, called the concave, also change how the board feels when you're turning. It's like the difference between a flat track and a race car track with banked curves. And the length? That matters too! A shorter deck might be easier for younger skaters, while a longer one can give you more foot room. Choosing the right size can definitely help if you want to use skateboarding to lose weight since you'll be more comfortable and able to ride longer.

Rolling Away: The Craft Behind the Deck

So, the next time you're admiring a fresh deck or surveying the scars on your trusty steed, remember the process it undertook. From a humble maple log to a precisely shaped platform, the creation of a skateboard deck is a testament to process and precision. It's a blend of natural materials and human ingenuity that allows us to push boundaries and experience the thrill of rolling.