Table of Contents

Ever watched a skater effortlessly carve a turn and wonder about the magic beneath their feet? That "magic" comes down to the humble skateboard truck. But these essential pieces of equipment don't just appear out of thin air. The process of how skateboard trucks are made involves some cool science and a bit of engineering know-how. We're going to break down exactly how these crucial components go from raw materials to the parts that help you shred. Think of it like this: your skateboard deck is the stage, your wheels are the actors, and your trucks? They're the stagehands, making sure everything runs smoothly and you don't faceplant. So, let's pull back the curtain and see how these unsung heroes of the skateboarding world are brought to life. You might be surprised at the process they take before they're bolted onto your board.

Key Aspect | Details |

|---|---|

Materials | High-quality trucks often use aluminum for lightness and good grinding. Stronger, but heavier, trucks might use steel. Premium options sometimes feature titanium for a balance of strength and weight. Axles are usually made of strong 4140 steel. |

Manufacturing Methods | Two main ways trucks are made are die-casting and gravity casting. Gravity casting is often preferred for stronger trucks with sharper details. |

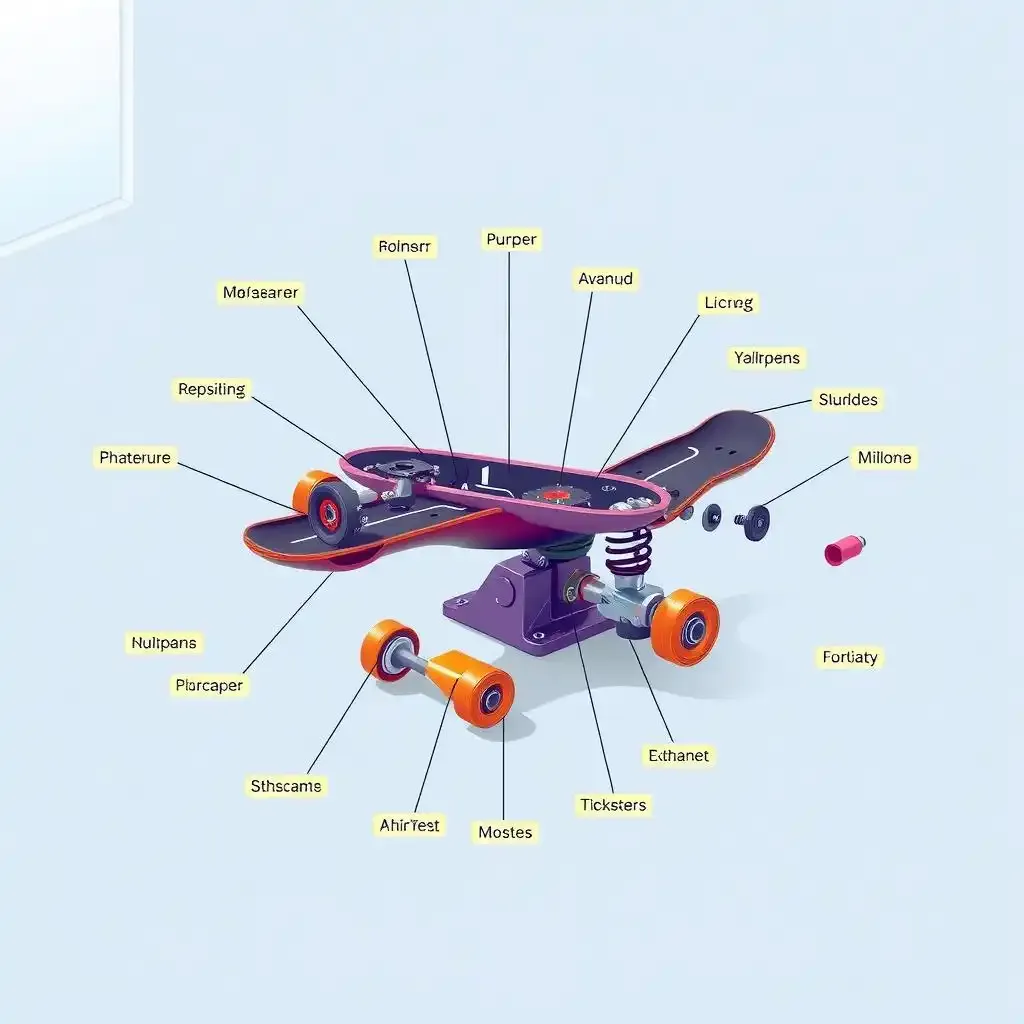

Key Components | The baseplate attaches to the board. The hanger is the main part that holds the axle and pivots for turning. The kingpin holds the hanger and baseplate together. Bushings cushion the ride. The axle holds the wheels. |

Customization | Manufacturers offer various customizations, like different colors, logo printing, and bushing hardness. You can even get lightweight options. |

Breaking Down Skateboard Trucks: Understanding the Parts

Breaking Down Skateboard Trucks Understanding The Parts

The Foundation: Baseplate and Kingpin

Okay, so imagine your skateboard truck is like a tiny car for your feet. The first big part you'll see is the baseplate. Think of it as the car's chassis, it's the flat piece that screws right onto the bottom of your deck. This part is super important because it's the anchor for everything else. Sticking out of the middle of the baseplate is the kingpin, a big bolt that holds a lot of the truck together, kind of like the main support beam in a treehouse. It’s what lets the truck turn, so it’s pretty crucial for carving around.

Turning Strength: Hanger and Bushings

Now, the part that actually holds your wheels is called the hanger. It's the beefy, T-shaped piece that hangs down from the baseplate. This is where the axle goes through, but we'll get to that. The cool part about the hanger is how it connects to the baseplate. It doesn't just sit there stiffly. There are these squishy rubbery bits called bushings nestled around the kingpin. These bushings are like tiny shock absorbers, and they're what let you lean into your turns. If you're curious about keeping your board in top shape, you might wonder, can skateboards handle getting wet? Knowing your trucks helps you understand what parts need extra care.

Wheels On: Axle and Speed Rings

Finally, we get to the axle. This is a solid rod of metal that runs right through the hanger. It's what your wheels spin on. You bolt your wheels onto the axle using axle nuts. But here's a little secret weapon: speed rings. These are thin washers that go on either side of your wheel, between the wheel and the hanger, and between the wheel and the axle nut. They might seem small and unimportant, but they're like tiny superheroes that reduce friction, helping your wheels spin faster and smoother. It's all these bits working together that let you cruise and do tricks. Ever wondered if all these truck parts are the same across different boards? It's a good question!

Part | What it Does |

|---|---|

Baseplate | Attaches the truck to the skateboard deck. |

Kingpin | Holds the baseplate and hanger together and allows turning. |

Hanger | Holds the axle and wheels, pivots for turning. |

Bushings | Cushion the ride and affect turning responsiveness. |

Axle | The rod that the wheels spin on. |

Speed Rings | Reduce friction for smoother, faster wheel spin. |

How Skateboard Trucks Are Made: From Molten Metal to the Streets

Okay, so making skateboard trucks is seriously cool. Imagine you're making a giant metal ice cube, but instead of water, we're using super-hot melted metal! That's kind of how it starts. Most skateboard trucks begin their life as solid chunks of aluminum or sometimes steel. These big blocks get tossed into a furnace, like a pizza oven but way hotter, until they turn into liquid metal, all glowy and bubbly. It’s like melting down all your old soda cans, but on a massive scale.Now, here's where the magic happens. There are two main ways to shape this molten metal into the truck parts we know. One way is called die-casting. Think of it like using a giant metal cookie cutter. The hot liquid metal gets squirted into a mold, which is like a super-precise metal form in the shape of the truck part. It fills up all the nooks and crannies, and then it cools down super fast. Poof! You've got a truck part. It's kind of like making those little chocolate shapes you get at Easter. Ever wondered if ? Well, these molds make sure they're all the right size and shape.The other way is called gravity casting, and this is how they make the really strong, high-quality trucks. Imagine pouring pancake batter into a pan. With gravity casting, they slowly pour the molten metal into a mold, letting gravity do the work to fill it up. This way takes a bit longer, but it makes the metal denser and stronger, kind of like how a slow-cooked stew tastes way better. These trucks can really take a beating when you're trying to grind that rail. Speaking of taking a beating, are skateboards dangerous? Knowing how tough the trucks are might make you feel a bit better!

After the metal cools, whether it was squirted in or poured in, the rough truck parts come out of the molds. They don't look all shiny and perfect yet. There's often extra bits of metal hanging off, kind of like the extra plastic on a model airplane kit. So, they get cleaned up, smoothed out, and sometimes even polished to make them look all slick. Think of it like giving your toy car a really good wash and wax.Then come the axles. These are usually made of super-strong steel, like what they might use to build a bridge. They get carefully pushed or hammered into the hanger part of the truck. It's a tight fit to make sure they don't wobble around when you're skating. Remember those squishy bushings? They get added around the kingpin hole, and then the kingpin itself gets shoved through, holding everything together. It’s like building with LEGOs, but with metal! If you’re thinking about trying some skate tricks, you might wonder, can skateboarding help lose weight? Having solid trucks is definitely important for that!Finally, before they’re ready to hit the skateparks, each truck gets checked to make sure it’s strong and works perfectly. It's like a quality control superhero making sure no bad trucks sneak out. They check for cracks, make sure everything is lined up, and that the axles are solid. Then, bam! You've got a brand-new skateboard truck, ready to be bolted onto a deck and ridden hard. It’s a pretty awesome trip from a chunk of metal to something that lets you fly!

Choosing Your Ride: Factors Influencing How Skateboard Trucks Are Made

Choosing Your Ride Factors Influencing How Skateboard Trucks Are Made

What's Your Style? Truck Types Explained

Alright, so you're probably thinking, "Trucks are trucks, right?" Nope! Just like there are different kinds of shoes for different sports, there are different kinds of skateboard trucks made for different ways of skating. Imagine you're picking out a bike. A mountain biker needs something super sturdy to handle jumps and bumps, while someone who cruises around the neighborhood might want something lighter and easier to steer. It's the same with skate trucks! If you're into doing flip tricks at the skatepark, you might want lighter trucks. These are often made with specific types of aluminum using die-casting. They're like the sports cars of the truck world – built for speed and agility. On the other hand, if you're dreaming of bombing hills or cruising long distances, you might prefer something a bit more solid, maybe even made with gravity casting for extra strength. Think of those like the SUVs – reliable and built to last. Have you ever wondered if ? Knowing your skating style helps you figure out what kind of truck construction is best for you.

Material Matters: Aluminum vs. Steel vs. Titanium

Now, let's talk about what these trucks are actually made of. It's like the ingredients in your favorite snack – they make a big difference! Most skateboard trucks you see are made of aluminum. It's like the go-to ingredient because it's light but still pretty strong. Think of an aluminum can – it's not super heavy, but it holds your soda just fine. But there are different kinds of aluminum, and some are stronger than others. Sometimes, for entry-level boards or for folks who want super durable trucks (even if they're a bit heavier), you'll find trucks made of steel. Steel is like that super strong friend who can always help you move furniture. It can take a beating, but it adds some extra weight. Then there's the fancy stuff: titanium. Titanium is like the superhero material – super strong AND super light. But just like superhero gadgets, titanium trucks can be a bit pricier. It's all about finding the right balance for your needs and your wallet. Remember when we talked about ? The materials your trucks are made from can affect how they hold up in different conditions too.

The Nitty-Gritty: Manufacturing Methods and Customization

So, we've talked about the different types of trucks and the materials. But how do they actually get made? We touched on it before, but the two main ways are die-casting and gravity casting. Die-casting is like using a giant injection mold. Imagine squirting hot metal into a mold like you're making a plastic toy. It's fast and good for making lots of trucks quickly. Gravity casting, on the other hand, is a slower process, like carefully pouring batter into a waffle iron. This method often results in stronger trucks because the metal is denser. And guess what? You can even customize your trucks! Companies let you pick different colors – imagine bright pink or electric blue trucks! You can sometimes even get your own logo printed on them. Plus, you can choose how hard or soft you want the bushings to be. Think of bushings like the volume knob on your skateboard – they control how easily your board turns. So, when you're choosing your trucks, it's not just about the metal; it's about how they're made and how you can make them your own.

The Grind is Real: From Factory to Flip Tricks

Next time you're landing a sweet trick (or maybe just trying not to fall), remember the process your skateboard trucks took to get there. From molten metal to the streets, it's a process that blends precision with a bit of brute force. Who knew so much went into those hunks of metal that let you grind down a handrail? Now, armed with this knowledge, you can appreciate the engineering that goes into every ollie, every kickflip, and every near-miss with a parked car. Go forth and shred, you magnificent board rider, you!